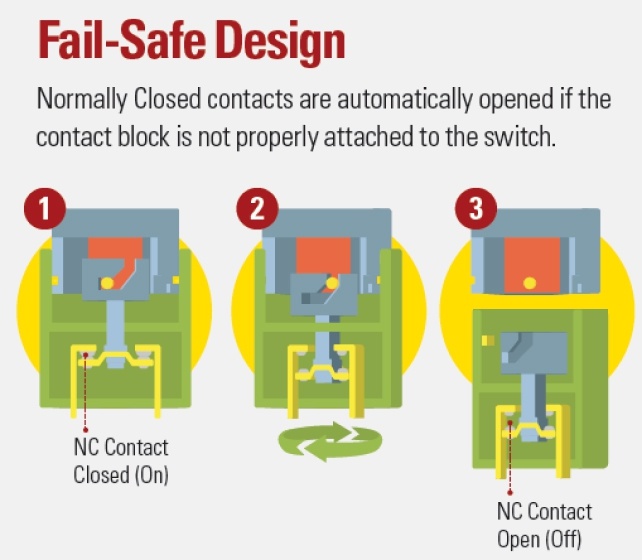

An Emergency-stop switch is reputed to ensure a machine stops when all other stop systems have failed. It is a complimentary measure that addresses the unforeseen hazard. Its performance on demand should never be in question and yet many E-stops cannot perform their safety function at the critical moment.

Do you know if you are taking that risk?

To make sure you make the right choice, we invite you to view our webinar "Would you trust your E-stop with your life?” and/or download our white paper.